Why You Need a Box Packing Machine for Your Business Efficiency

In today's fast-paced business environment, maximizing operational efficiency is crucial for staying competitive and satisfying customer demands. One of the most significant advancements in modern packaging solutions is the box packing machine. This innovative equipment streamlines the packing process, significantly reducing the time and labor involved in preparing products for shipment. By automating the box packing process, businesses can allocate their resources more effectively, improving overall productivity and allowing staff to focus on more strategic tasks.

Adopting a box packing machine not only enhances efficiency but also ensures consistency and accuracy in packaging. With the capability to handle various box sizes and types, these machines minimize the risk of human error, leading to fewer returns and greater customer satisfaction. Moreover, an efficient packing system contributes to reduced material waste, which is essential for companies striving for sustainability. Ultimately, integrating a box packing machine into your business operations can revolutionize your packing strategy, driving growth and enhancing your competitive edge in the marketplace.

Understanding the Role of Box Packing Machines in Business Efficiency

Box packing machines play a crucial role in enhancing business efficiency by streamlining the packaging process. In today’s fast-paced market, the demand for quick and reliable packaging solutions is higher than ever. These automated machines significantly reduce manual labor by quickly assembling and sealing boxes, which not only saves time but also minimizes the risk of errors that can occur during manual packing. This results in a more organized workflow where employees can focus on more value-added tasks rather than spending excessive time on repetitive packing duties.

Moreover, the consistency and quality of packaging provided by box packing machines contribute to better product presentation and customer satisfaction. A well-packaged product enhances the unboxing experience, leading to positive customer impressions and stronger brand loyalty. Additionally, these machines can adapt to various box sizes and materials, making them versatile for different business needs. Overall, the integration of box packing machines in a business model not only boosts productivity but also plays a vital role in maintaining high standards of quality and efficiency in the supply chain.

Key Benefits of Implementing Box Packing Machines in Operations

Implementing box packing machines in business operations can significantly enhance efficiency and productivity. According to a report from the Packaging Industry Association, automating the packing process can reduce labor costs by up to 30%. Additionally, companies often see a 50% increase in packing speed, which allows for faster order fulfillment and improved customer satisfaction. Utilizing such machines minimizes human error, resulting in more consistent packaging quality, which is crucial for maintaining brand reputation.

Moreover, box packing machines tailor the packaging process to suit various sizes and types of products, which enhances flexibility in operations. A study by the Institute of Packaging Professionals indicates that businesses can cut material waste by approximately 15% when utilizing automated packing systems. This not only leads to cost savings but also supports sustainability efforts, resonating with an increasingly eco-conscious consumer base.

Tip: When choosing a box packing machine, consider models that offer adjustable settings for different product sizes to maximize versatility. Also, integrating advanced technology such as sensors and automatic labeling can further improve accuracy and speed in packing operations. Training staff to efficiently operate these systems is equally essential to fully realize their capabilities and ensure seamless integration into existing workflows.

Why You Need a Box Packing Machine for Your Business Efficiency - Key Benefits of Implementing Box Packing Machines in Operations

| Benefit | Description | Impact on Efficiency |

|---|---|---|

| Increased Speed | Automates the packing process, significantly reducing packing time. | Reduces packing time by up to 50%. |

| Consistency and Quality | Ensures uniform packing, minimizing errors and improving product presentation. | Improves quality by reducing defects in packing. |

| Labor Savings | Reduces the need for manual labor, allowing staff to focus on higher-value tasks. | Decreases labor costs by up to 30%. |

| Space Efficiency | Compact design allows for better use of warehouse space. | Maximizes space utilization by up to 25%. |

| Improved Safety | Reduces the risk of injury associated with manual packing operations. | Decreases workplace accidents by enhancing safety measures. |

How Box Packing Machines Reduce Labor Costs and Time

In today's fast-paced business environment, efficiency is paramount, and box packing machines are becoming essential tools for companies looking to enhance productivity. These machines streamline the packing process by automating tasks that would typically require multiple workers. By reducing the need for manual labor, businesses can significantly cut down on labor costs, allowing them to allocate resources more effectively to other critical areas.

Moreover, box packing machines optimize time management in the packing workflow. They can process a larger volume of products in a shorter period, enabling businesses to meet higher demand without the bottlenecks that often occur with manual packing methods. This increased efficiency not only improves throughput but also enhances overall operational effectiveness. As a result, companies can maintain better customer satisfaction by ensuring timely delivery of products, reinforcing the importance of adopting automated packing solutions in a competitive market.

Comparing Manual Packing versus Automated Box Packing Solutions

When comparing manual packing versus automated box packing solutions, it's crucial to acknowledge the stark differences in efficiency and cost effectiveness. According to a report published by the Packaging Machinery Manufacturers Institute (PMMI), companies that adopt automated packaging solutions can witness a productivity increase of up to 30%, significantly reducing labor costs. Manual packing, while flexible, often leads to inconsistencies that contribute to material waste and increased shipping errors. A study by the International Society for Automation suggests that automation can also decrease packing time by as much as 50%, allowing businesses to meet growing consumer demands more effectively.

Tips for businesses considering automation: Start by analyzing your current packing processes. Identifying bottlenecks in your manual packing can highlight areas where automation could significantly enhance productivity. Additionally, consider integrating automated systems that can adapt to various product sizes and shapes; this fosters seamless transitions between different packing tasks without the need for extensive reconfiguration.

Furthermore, investing in a box packing machine not only optimizes operational efficiency but also improves workplace safety. Manual packing often requires repetitive motion that can lead to employee fatigue or injury. In contrast, automated solutions can minimize these risks while delivering precise packaging with consistent quality. A recent survey conducted by the National Safety Council indicates that companies adopting automation report a reduction in workplace injuries by over 40%. Such improvements can lead to fewer disruptions and a more motivated workforce, ultimately benefitting the overall business performance.

Factors to Consider When Choosing a Box Packing Machine for Your Business

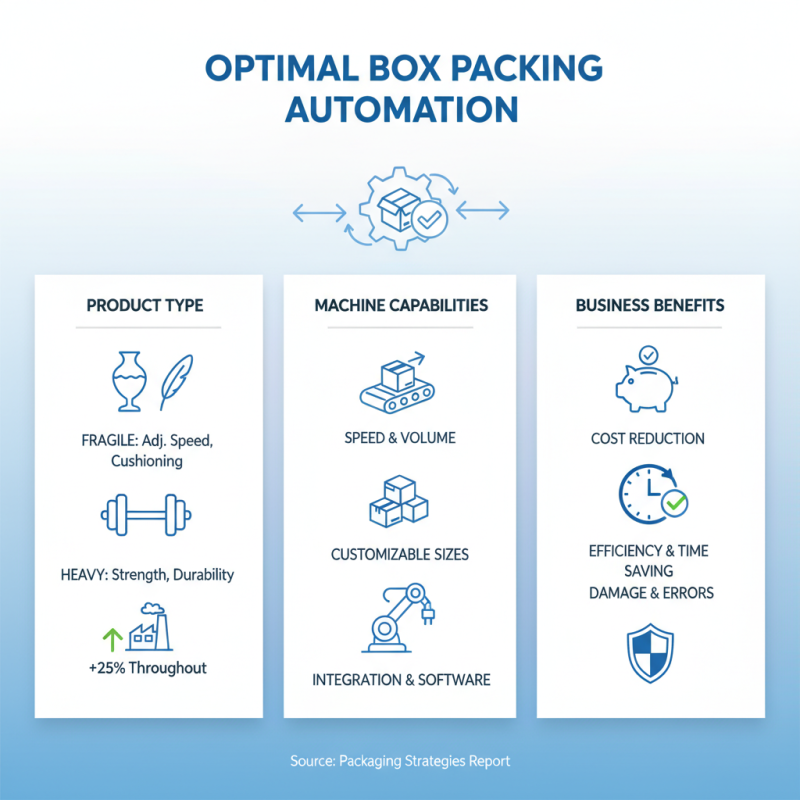

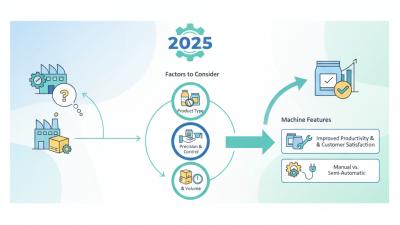

When considering a box packing machine for your business, several critical factors come into play that can dramatically enhance operational efficiency. Firstly, the type of products being packed should inform your choice. According to a report by Packaging Strategies, industries have reported a 25% increase in throughput after implementing automation tailored to their specific products. For instance, fragile items may require machines with adjustable speed and customized cushioning options, while heavier products might prioritize strength and durability in packaging.

The size and dimensions of the machine also play a significant role in optimizing space and operations. A survey conducted by the Packaging Machinery Manufacturers Institute (PMMI) highlights that businesses struggle with floor space; 60% of surveyed companies noted that packaging machinery takes up valuable real estate in their facilities. Thus, selecting a compact, scalable machine that can fit into existing production lines without disrupting workflow is essential. Additionally, ease of operation and maintenance should not be overlooked. Machines that are complicated to operate can lead to training bottlenecks, damaging productivity. As revealed by recent market studies, up to 40% of unplanned downtime in production environments is due to operator error, a statistic that can be mitigated by investing in intuitive machinery with user-friendly interfaces.

Related Posts

-

Top Benefits of Using a Box Packing Machine in Your Packaging Process

-

What is a Pouching Machine? Understanding Its Uses and Benefits

-

The Ultimate Guide to Pouching Machines in 2025 for Packaging Solutions

-

2025 Top Trends in Chemical Packaging Machine Industry You Need to Know

-

2025 Guide: How to Choose the Best Manual Pouch Filling Machine