What is a Pouching Machine? Understanding Its Uses and Benefits

A pouching machine is an essential piece of equipment in various industries, designed to automate the process of filling and sealing pouches. With its ability to enhance efficiency and consistency, it has become increasingly popular in sectors such as food packaging, pharmaceuticals, and consumer goods. The advantages of utilizing a pouching machine are vast, including reduced labor costs, improved productivity, and the capability to maintain stringent hygiene standards during packaging processes.

Understanding the uses and benefits of a pouching machine can help businesses optimize their operations and meet the growing demands of consumers for convenient and properly packaged products. By exploring the various applications of this technology, from granules and liquids to powders, companies can tailor their packaging strategies to suit their specific needs. As the market continues to evolve, the pouching machine stands out as a pivotal tool that not only meets current packaging challenges but also paves the way for innovative solutions in product presentation and preservation.

What is a Pouching Machine? An Overview

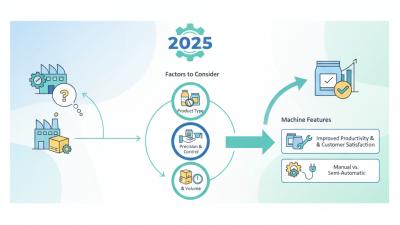

A pouching machine is a specialized device designed for the efficient packaging of a variety of products into flexible pouches. These machines are crucial in industries such as food and beverage, cosmetics, and pharmaceuticals, where speed and precision play a significant role in production processes. According to industry research by MarketsandMarkets, the global pouching machinery market is expected to reach approximately $6.5 billion by 2025, driven by the increasing demand for packaged goods and the need for automation in manufacturing.

The primary function of pouching machines is to create pouches that are both functional and aesthetically pleasing. They come equipped with advanced features that allow for customization in terms of size, shape, and material, meeting the specific needs of different products. The efficiency delivered by these machines can lead to reduced labor costs and increased production rates. A report from Grand View Research highlights that automation in packaging, like that offered by pouching machines, can enhance productivity by as much as 20-30%, making them an essential asset for manufacturers looking to streamline their operations and improve profitability. Additionally, the use of pouches minimizes waste, aligning with sustainability goals that are increasingly important in today’s market.

In summary, pouching machines represent a vital innovation in packaging technology, changing how products are presented and preserved. Their benefits extend beyond packaging efficiency, positively impacting overall operational costs and environmental sustainability, making them a significant investment for businesses across multiple industries.

How Pouching Machines Work: A Step-by-Step Guide

A pouching machine is a versatile piece of equipment designed primarily for packaging goods in durable pouches. Understanding how these machines operate is essential for businesses looking to enhance their packaging processes. The operation begins with the feeding of packaging materials, typically in roll form, into the machine. As the material is drawn in, it gets heated and sealed to form the basic structure of the pouch.

The next step involves the precise measurement and filling of the pouch with the desired product, whether it be liquids, powders, or solid items. This is typically achieved through volumetric or weight-based filling mechanisms, ensuring each pouch is uniformly filled. After filling, the machine seals the pouch airtight to maintain product freshness and prevent leakage. The final phase includes cutting the pouches to the specified size, allowing them to be easily packaged for distribution.

This automated process not only improves efficiency but also significantly reduces the labor costs associated with manual packaging. Pouching machines are particularly beneficial in industries such as food and beverage, pharmaceuticals, and consumer goods due to their ability to provide a reliable and consistent packaging solution.

| Feature | Description | Benefits |

|---|---|---|

| Speed | Pouching machines can produce bags at a rapid pace, increasing overall productivity. | Reduces labor costs and enhances efficiency in production lines. |

| Versatility | Can package a variety of products from food to pharmaceuticals. | Offers flexibility for different industries and product types. |

| Customizable | Pouching machines can be tailored to specific pouch sizes and designs. | Enhances brand identity and product presentation. |

| Automation | Many machines offer automated filling and sealing processes. | Lowers the chance of human error and improves safety. |

| Space Efficiency | Pouching machines typically require less floor space compared to traditional packaging methods. | Maximizes use of available workspace in production facilities. |

Various Types of Pouching Machines and Their Applications

Pouching machines are versatile tools in packaging operations, designed to create pouches that can hold various products. There are several types of pouching machines, each tailored for specific applications and industries.

For instance, vertical form fill seal (VFFS) machines are widely used in the food industry. They form pouches from rolled film, fill them with products such as snacks or powders, and seal them, ensuring high efficiency and reduced labor costs. This type of machine is especially beneficial for companies aiming to streamline their packaging processes while maintaining product freshness.

Another common type is the horizontal form fill seal (HFFS) machine, ideal for products that require a different approach to packaging. HFFS machines are often used for items like granola bars or frozen foods, where the orientation of the product is important for effective sealing. These machines involve horizontal movement, offering enhanced versatility in accommodating diverse product sizes and shapes.

Additionally, pre-made pouching machines provide the advantage of using ready-made pouches, which allows for quicker changeovers and is particularly beneficial in industries that require a fast turnaround time for different products. Each type of pouching machine optimizes the packaging process, catering to the unique requirements of various sectors, thus maximizing operational efficiency and product safety.

Key Benefits of Using Pouching Machines in Industries

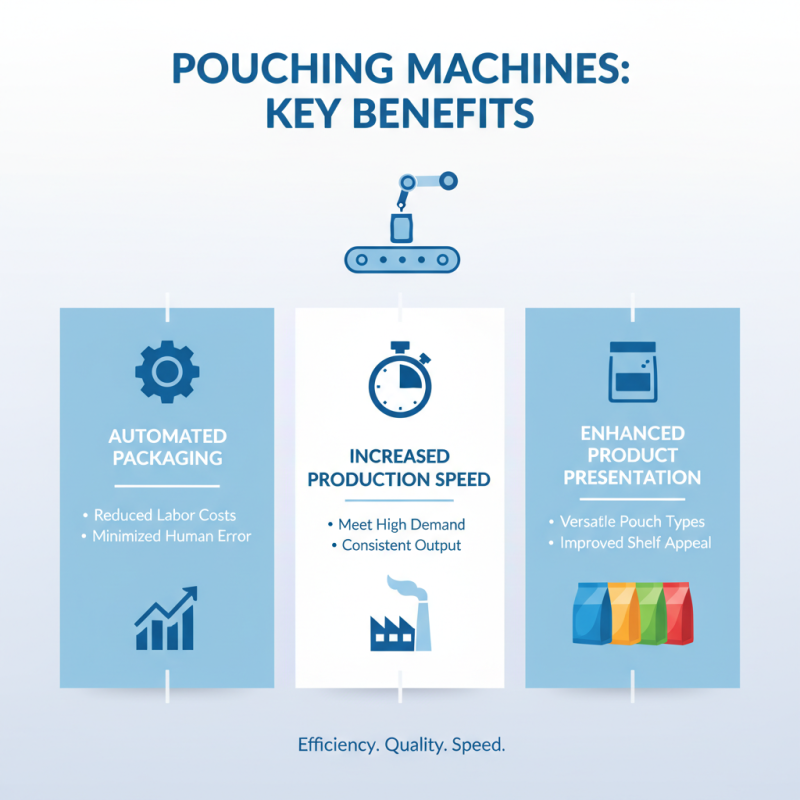

Pouching machines have become essential tools in various industries, offering numerous advantages that enhance packaging efficiency and product presentation. One of the key benefits of using pouching machines is their ability to automate the packaging process, which significantly reduces labor costs and minimizes human error. This automation enables businesses to increase production speed, allowing them to meet high demand without compromising on quality. Moreover, pouching machines can operate continuously, ensuring a consistent output that supports larger-scale operations.

Another notable advantage is the versatility of pouching machines. They can accommodate a wide range of pouch types and sizes, making them suitable for diverse products, from food items to pharmaceuticals. This flexibility allows companies to adapt quickly to changing market demands and introduce new products without the need for significant reconfiguration. Additionally, pouching machines often incorporate advanced technology that ensures precise filling and sealing, which not only enhances product freshness but also improves shelf life. Overall, the integration of pouching machines into production lines leads to improved operational efficiency and enhanced product appeal.

Maintenance and Best Practices for Pouching Machines

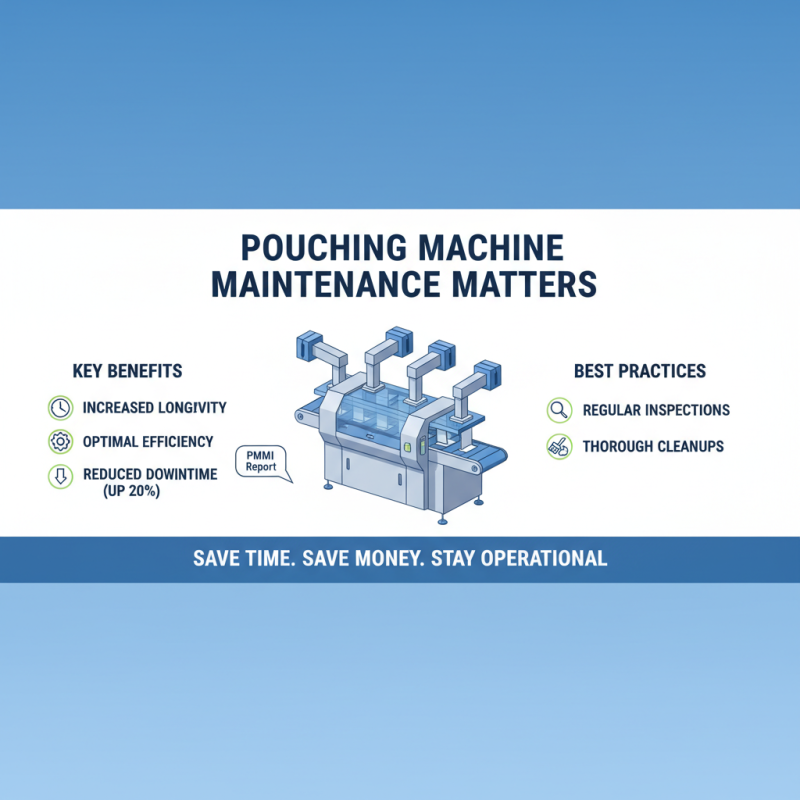

Pouching machines are essential in various industries, particularly in food packaging, pharmaceuticals, and cosmetics. Proper maintenance of these machines is crucial for ensuring their longevity and operational efficiency. Regular inspections and cleanup are fundamental best practices. According to a report from the Packaging Machinery Manufacturers Institute (PMMI), well-maintained pouching equipment can reduce downtime by up to 20%. This is significant as machine downtime can lead to substantial losses, both in productivity and revenue.

In addition to regular cleaning and inspections, it is vital to adhere to the manufacturer’s guidelines for lubricating and calibrating the machine. The International Society for Food Engineering emphasizes that maintaining precise calibrations not only enhances package quality but also optimizes material use, potentially leading to a 15% reduction in waste. Furthermore, staff training on machine operation and troubleshooting can instill a proactive maintenance culture, further bolstering productivity and extending the machine’s lifespan. Investing in maintenance and training can yield a return on investment that justifies the initial costs, making it a financially sound decision for operations relying on pouching technology.