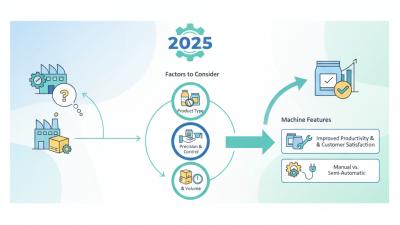

The Ultimate Guide to Pouching Machines in 2025 for Packaging Solutions

As we venture into 2025, the packaging industry is poised for a substantial transformation, particularly in the domain of pouching machines. This highly specialized machinery has seen a notable rise in adoption across various sectors, attributed to the increasing demand for lightweight, cost-effective, and sustainable packaging solutions. According to a recent report by the International Packaging Association, the global pouch packaging market is projected to reach USD 45 billion by 2025, underscoring the growing preference for flexible packaging formats which pouching machines facilitate effectively.

Industry expert Dr. Emily Chen notes, “The advancement of pouching machines not only enhances efficiency and reduces material waste but also meets the evolving consumer expectations for convenience and sustainability.” This statement encapsulates the driving factors behind the escalating interest in pouching technologies. With innovations in automation and digital integration, pouching machines are becoming increasingly sophisticated, allowing manufacturers to optimize production processes while ensuring high-quality standards.

In this ultimate guide, we will explore the key trends and technological advancements that are shaping the future of pouching machines. From new designs that cater to diverse product types to smarter systems that provide real-time data analytics, the insights presented will equip stakeholders with the knowledge necessary to navigate this dynamic landscape and harness the potential of pouching solutions for their packaging needs.

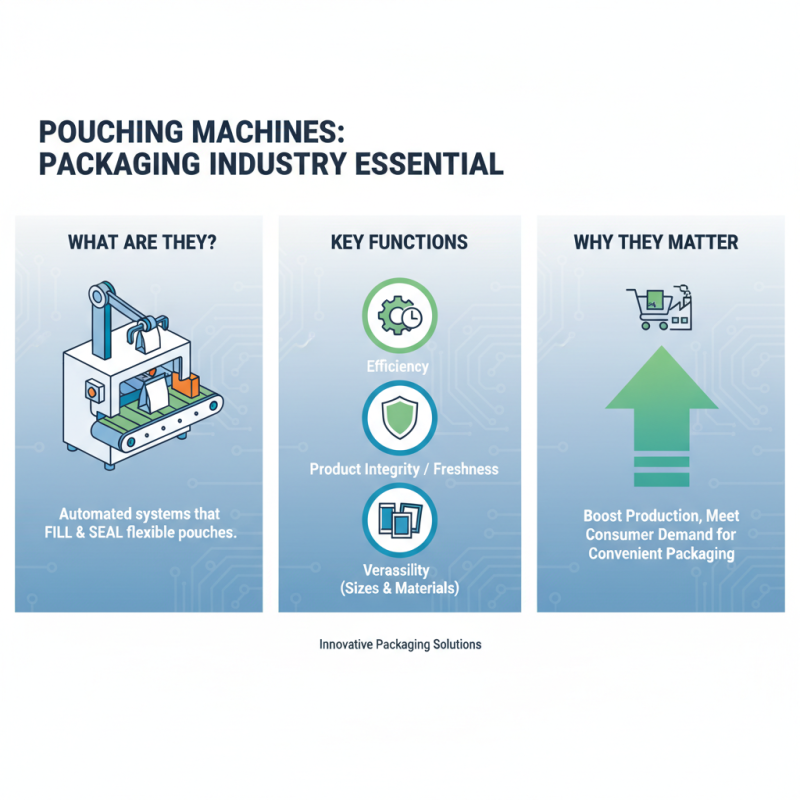

Overview of Pouching Machines: Definition and Importance

Pouching machines play a vital role in the packaging industry by providing efficient and versatile solutions for a variety of products. Defined as automated systems designed to fill and seal pouches, these machines facilitate the packaging of items ranging from food and beverages to consumer goods and pharmaceuticals. Their importance lies not only in enhancing production efficiency but also in ensuring the integrity and freshness of the products sealed within. With their ability to manage different pouch sizes and materials, pouching machines have become indispensable in meeting the growing demand for convenient packaging options.

Moreover, the significance of pouching machines extends to sustainability and cost-effectiveness in packaging practices. As consumers increasingly prefer eco-friendly products, pouching machines can utilize recyclable materials and reduce waste through precise material usage. Additionally, the automation and speed of these machines contribute to lower labor costs and higher throughput, which are critical in today's competitive marketplaces. Thus, pouching machines not only streamline the packaging process but also align with the industry's shift towards sustainable practices while meeting consumer expectations for quality and convenience.

Key Technologies Driving Pouching Machine Innovations in 2025

In 2025, the pouching machine industry is set to experience a significant transformation driven by several key technologies. Advanced automation and robotics are central to this innovation wave, enhancing the efficiency of production lines. According to a recent market report, the integration of robotics in pouching machines is projected to reduce operational costs by up to 30%, enabling manufacturers to scale operations while maintaining high precision and speed. These enhancements in automation are paving the way for smarter packaging solutions that can adapt quickly to changing consumer demands.

Moreover, the rise of sustainable packaging is pushing the development of pouching machines to utilize eco-friendly materials and processes. Reports indicate that the global market for sustainable packaging is forecasted to reach $500 billion by 2026, driving the need for machines that are capable of handling biodegradable and recyclable materials. This shift not only helps companies meet regulatory requirements but also aligns with consumer preferences for environmentally conscious products.

Tips: When considering a pouching machine for packaging solutions, assess the machine's capability to handle diverse materials to future-proof your operations. Additionally, explore options that incorporate automation features, as these can significantly lower labor costs and increase production efficiency. Emphasizing sustainability in packaging design will not only reflect positively on your brand but also attract a growing segment of eco-conscious consumers.

Types of Pouching Machines and Their Applications in Various Industries

The pouching machine market is poised for significant growth by 2025, driven by the increasing demand for flexible packaging solutions across various industries. According to a report by Grand View Research, the global flexible packaging market is projected to reach USD 400 billion by 2025, with pouches being a major contributor to this expansion. Different types of pouching machines serve a myriad of applications, from food and beverages to pharmaceuticals and personal care products, enabling companies to enhance efficiency and reduce waste in their packaging processes.

In the food and beverage sector, stand-up pouches have gained popularity due to their convenience and space-saving design. These machines are engineered to accommodate various materials and sizes, allowing for customization that meets specific industry needs. For instance, the food industry relies heavily on premade pouch filling machines, which facilitate quick packing for products like snacks, sauces, and frozen foods. A report by Research and Markets indicates that the food packaging segment alone accounts for over 40% of the overall pouching machine market, highlighting its pivotal role in this sector.

Pharmaceuticals also leverage pouching technology, particularly in the packaging of powders and tablets. Rollstock pouching machines, which create pouches from a single film roll, have been increasingly adopted for their efficiency and ability to maintain product integrity. The Market Research Future report anticipates a growth rate of approximately 5.1% CAGR for pharmaceutical pouching, underscoring the rising emphasis on safety and compliance within the industry. These advancements in pouching technology not only optimize production but also enhance user experience through innovative designs tailored for specific applications.

Sustainability Trends in Pouching Machine Design and Materials

The packaging industry is witnessing a significant shift towards sustainability, particularly in the design and materials of pouching machines. As consumers become increasingly environmentally conscious, manufacturers are responding by integrating eco-friendly practices into their operations. According to a recent report from the Packaging Association, over 75% of consumers are willing to pay more for sustainable packaging, compelling companies to prioritize green solutions. This trend is driving innovations in materials, with a surge in demand for biodegradable and recyclable options, such as plant-based polymers and compostable films.

Pouching machines are adapting to these changes by incorporating technology that minimizes waste and energy consumption. For instance, newer models are designed to reduce excess film usage while improving sealing efficiency. In fact, the industry has seen a 30% reduction in material waste from advanced pouching technologies, enhancing both sustainability and profitability. Furthermore, manufacturers are focusing on lifecycle assessments to ensure that the materials used throughout a pouch's lifecycle contribute positively to the environment.

Tips: When selecting a pouching machine, consider those that offer features enabling easy changeovers and adjustments to accommodate different eco-friendly materials. This flexibility can greatly enhance your production efficiency while supporting sustainable practices. Additionally, invest in training for your staff on the importance of sustainability in packaging to foster a culture of eco-consciousness within your operations.

The Ultimate Guide to Pouching Machines in 2025 for Packaging Solutions - Sustainability Trends in Pouching Machine Design and Materials

| Feature | 2025 Standard | Sustainability Metrics | Innovative Materials |

|---|---|---|---|

| Energy Efficiency | < 1.2 kWh per pouch | 30% reduction in energy consumption | Recycled plastics |

| Material Use | Minimal waste production | 50% biodegradable materials | Plant-based films |

| Production Speed | 300 pouches/min | Reduces carbon footprint | Composite materials |

| Automation Level | Fully automated systems | Less labor-intensive | Smart polymers |

| Recyclability | >90% recyclable content | Support closed-loop systems | Bio-sourced laminates |

Future Trends and Predictions for Pouching Machines Post-2025

As we look towards 2025 and beyond, the pouching machine industry is poised for transformative growth driven by technological advancements and evolving consumer preferences. A report from Smithers Pira estimates that the global pouch packaging market will exceed $49 billion by 2027, highlighting a strong shift towards flexible packaging solutions. This growth will be largely fueled by the demand for sustainable packaging, with consumers increasingly seeking environmentally friendly options. Innovative pouching machines are expected to incorporate features like reduced material usage and recyclability, aligning with the sustainability goals of manufacturers.

Moreover, automation and smart technology will play a central role in the future of pouching machines. According to a study by MarketsandMarkets, the automation in packaging will witness a compound annual growth rate of 14.8% from 2020 to 2025. This trend will lead to enhanced efficiency, higher output rates, and reduced labor costs, making pouching machines more competitive in the marketplace. The integration of IoT capabilities will further enable real-time monitoring and maintenance, driving down downtime and increasing operational efficiency, thus revolutionizing how products are packed and delivered in the upcoming years.