Essential Tips for Choosing a Small Sachet Filling Machine?

In the competitive landscape of the packaging industry, choosing the right small sachet filling machine is crucial. Recent industry reports indicate that the demand for sachet packaging continues to grow significantly, projected to reach $12 billion by 2026. This rise reflects an increasing consumer preference for convenience, portion control, and cost-effectiveness. A small sachet filling machine not only meets these needs but also enhances productivity and reduces wastage.

However, selecting the appropriate machine can be challenging. Buyers often overlook critical factors such as fill speed, machine size, and compatibility with various products. For example, some machines may struggle with powders or granules. Neglecting these details can lead to inefficiency and increased operational costs. Investing time in understanding machine specifications and performance capabilities is necessary to avoid future regrets.

Ultimately, the right small sachet filling machine can streamline operations and maximize profitability. Yet, it demands careful consideration and a reflective approach to ensure it aligns with specific business needs and product types.

Understanding the Different Types of Small Sachet Filling Machines

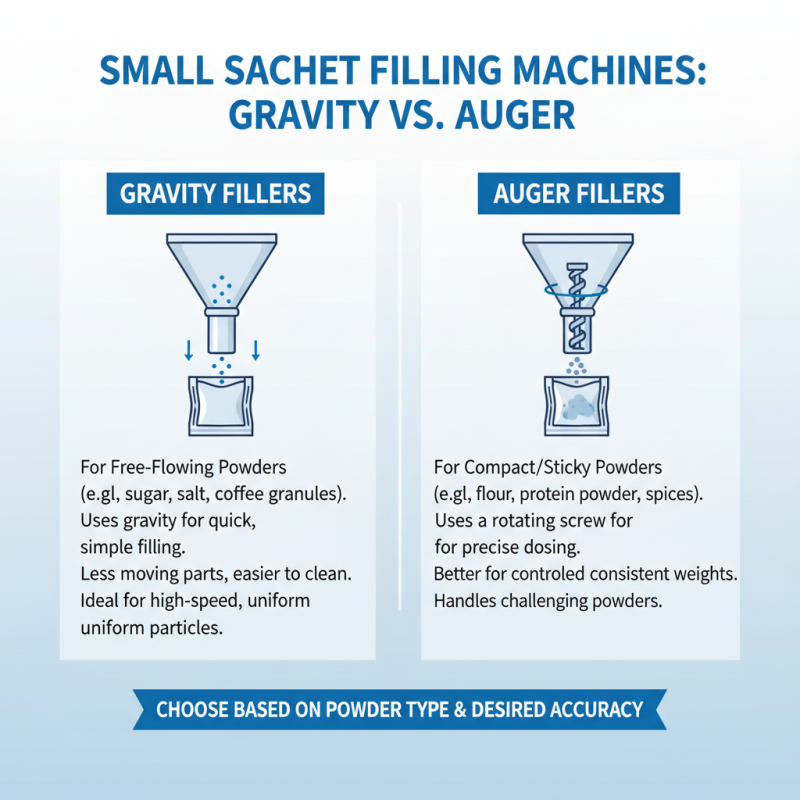

When considering a small sachet filling machine, it's essential to understand the different types available. They vary in design and functionality. Some machines use gravity filling, while others employ auger fillers. Gravity fillers work well for free-flowing powders. Auger fillers, on the other hand, are better suited for powders that are more compact or sticky.

While choosing a machine, consider the production capacity. Some machines fill a few hundred sachets per hour, while others can handle thousands. It's crucial to match the machine's speed with your production needs. Also, check the machine's adaptability for different sachet sizes. This flexibility can save costs and reduce wasted materials.

Another vital tip is to consider ease of cleaning and maintenance. Machines that are complicated may lead to operational glitches. If the machine is hard to clean, it can slow down production and increase waste. Reflect on this: A complex setup might seem efficient, but it can become a headache later on. Prioritize ease of use to keep operations running smoothly.

Key Factors Influencing the Selection of Sachet Filling Machines

When selecting a small sachet filling machine, various factors play a crucial role. The type of product being packaged is vital. Liquids, powders, and granulated goods require different machine features. According to a 2022 industry report, 45% of manufacturers reported issues with machines not suited for their specific products. This highlights the importance of matching the machine to your product type.

Speed and efficiency are also significant considerations. Many small businesses prioritize compactness. However, they still need machines that can operate quickly. A study showed that machines capable of filling 30-50 sachets per minute are favored by 60% of users. Yet, not all machines can sustain high speeds without compromising quality. This reflects the delicate balance in this choice.

The material of the sachet itself influences selection too. For instance, laminated films may require specialized sealing techniques. A 2023 survey revealed that 30% of users faced issues with sealing integrity. These problems can lead to product spoilage. Thus, selecting a machine adept at handling specific materials is essential for ensuring package integrity and product freshness.

Analyzing Production Capacity and Speed for Efficient Operations

When choosing a small sachet filling machine, analyzing production capacity and speed is crucial for efficient operations. The right machine should align with your production goals. A machine's capacity indicates how many sachets it can fill per hour. If your demand fluctuates, consider a machine that adapts easily to changes. This flexibility can save costs and time.

Speed is equally important. Faster machines may boost productivity, but they can also lead to errors. Finding a balance is essential. High speed does not guarantee quality. A slower machine may perform better with fewer rejects. It's vital to assess your product's nature. Some products require careful handling, impacting overall speed.

Investigate various machines; read reviews and gather feedback. Pay attention to settings that allow you to tweak speed and volume. Measuring these factors will guide your decision. Without careful analysis, you risk overworking your team or running inefficiently. Reflect on your operational needs before making a purchase. This thoughtfulness can lead to long-term success.

Evaluating Material Compatibility and Machine Versatility

When choosing a small sachet filling machine, material compatibility is crucial. Different materials require specific types of machines. For instance, granules may need a different fill mechanism than powders. Check the machine's specifications. Ensure it can accommodate the materials you plan to use. This can save time and costs in the long run.

Versatility in a machine is also important. A versatile machine can handle various products. This flexibility can be beneficial if you plan to expand your offerings. Look for machines with adjustable settings. This feature is key to adapting to different materials efficiently.

Here are some tips: always test the machine to assess its performance with your materials. Consider the ease of maintenance. A machine that is hard to maintain may lead to downtimes. Evaluate the support services available from the supplier. Think about how future changes in materials might affect your choice. Each decision should align with your long-term goals.

Essential Tips for Choosing a Small Sachet Filling Machine

| Dimension | Description |

|---|---|

| Machine Type | Automatic, Semi-Automatic |

| Filling Volume | 5g to 1000g |

| Material Compatibility | Powders, Granules, Liquids |

| Production Speed | 30 to 120 bags per minute |

| Power Supply | Single-phase or Three-phase |

| Versatility | Interchangeable parts for various sachet sizes |

| Control System | PLC or manual controls available |

| Maintenance | Easy access for cleaning and servicing |

Assessing Maintenance Requirements and After-Sales Support Options

When selecting a small sachet filling machine, assessing maintenance requirements is key. Machines can experience wear and tear over time. Regular maintenance minimizes downtime. Reports indicate that nearly 30% of production delays result from machine malfunctions. Understanding the maintenance schedule from the outset can save money and time later.

After-sales support is another crucial aspect. Often overlooked, it plays a significant role in machine operation. A responsive support team can help resolve issues quickly. Statistics show that effective after-sales support can enhance customer satisfaction by up to 25%. Ensure the provider offers comprehensive training and readily available parts.

Tip: Look for machines that offer easy access for maintenance tasks. A machine that's simple to maintain can lead to better operational efficiency.

When evaluating options, weigh the availability of support services. Investigate the average response times. Responsive support may be the difference between smooth production and frustrating delays. These factors significantly impact the overall value of the investment.

Related Posts

-

Top Robotic Packing Machines of 2026 What to Expect?

-

2026 Best Small Packaging Machine Options for Efficient Solutions?

-

Why You Need a Box Packing Machine for Your Business Efficiency

-

What is a Pouching Machine? Understanding Its Uses and Benefits

-

Top 10 Packaging Equipment Innovations You Need to Know About

-

2026 Top Small Box Packing Machine Innovations and Trends?