Top 10 Packaging Equipment Innovations You Need to Know About

In the fast-evolving world of packaging equipment, staying ahead is crucial. According to Sarah Thompson, a leading packaging technology expert, "Innovation in packaging equipment drives efficiency and sustainability." Her words resonate deeply within an industry that is constantly seeking improvement.

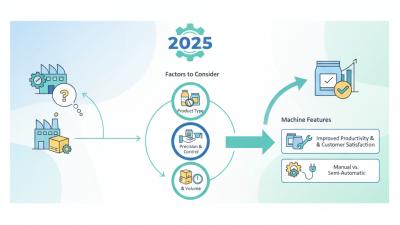

The top 10 packaging equipment innovations are revolutionizing processes. Advanced automation tools are streamlining production lines, yet challenges remain. Not all machines fit every product. Diverse product needs present unique hurdles for manufacturers.

Additionally, sustainability is a growing concern. While new equipment reduces waste, the transition often involves complexities. Older systems sometimes resist new technologies. Recognizing these flaws is essential to embrace the future. Packaging equipment must adapt not only to current demands but also anticipate future trends.

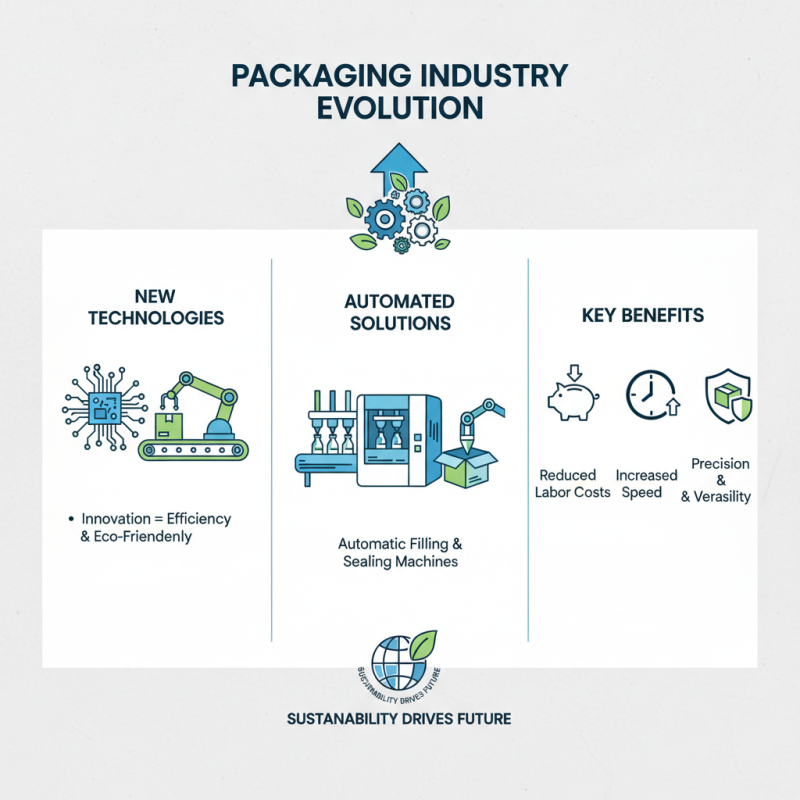

Overview of Packaging Equipment Innovations

The packaging industry is evolving rapidly. New technologies are reshaping how products are packed and delivered. Innovations are essential for efficiency and sustainability. Automatic filling and sealing machines are gaining popularity. They reduce labor costs while increasing speed. These machines can handle various packaging types with precision.

Tips: Consider investing in smart technology. It can optimize your supply chain. Analytics tools can help track performance.

Another exciting advancement is eco-friendly materials. Biodegradable films and recycled boxes are becoming common. Companies are under pressure to reduce waste. Innovative packaging not only meets consumer demands but also helps the planet. However, finding a balance between sustainability and cost is challenging. Experimentation is necessary to improve product offerings.

Tips: Always test new materials before full implementation. Observe how they perform in real conditions. Adjust your strategies based on feedback. This will minimize risks and enhance your packaging solutions.

Automation in Packaging: The Future of Efficiency

Automation is reshaping the packaging industry. The future demands efficiency and speed. Recent industry reports reveal that automated packaging systems can enhance productivity by up to 30%. Companies adopting automation typically report lower labor costs. An agile production line is crucial for meeting consumer demand.

Many manufacturers still rely on traditional methods. This can result in bottlenecks. There are benefits to modernization. For example, robotic packaging systems reduce errors and improve consistency. Implementing automated solutions leads to higher accuracy in product packaging. This reduces waste and saves resources.

**Tips:** Consider investing in flexible automation systems. These systems can adapt to various products. Regular assessment of current processes is vital. Keeping abreast of the latest innovations can prevent stagnation. Evaluate both short-term and long-term impacts of new technologies. Embrace change, but approach it thoughtfully.

Eco-Friendly Packaging Solutions: Trends and Developments

Eco-friendly packaging solutions are rising in popularity. Many companies now prioritize sustainable materials. They seek alternatives like biodegradable plastics and recycled paper. These materials reduce environmental impact. Consumers are increasingly aware of their choices. They prefer brands that support sustainability.

Innovations in packaging technology are essential. New designs help in reducing waste. Some packaging is now designed to be reused easily. However, the challenge remains in scalability. Not all eco-friendly options are cost-effective. Small businesses may struggle to adopt new solutions. There is also a question about performance. Can sustainable materials protect products as well as traditional ones?

As trends develop, brands must reevaluate their strategies. They need to find a balance between sustainability and practicality. Innovation shouldn’t compromise quality. The packaging industry is evolving, but it often feels slow. Continuous reflection and adaptation are crucial for meaningful progress.

Smart Packaging Technologies: Enhancing Consumer Experience

Smart packaging technologies are revolutionizing how brands connect with consumers. With the global smart packaging market projected to reach $37 billion by 2024, innovations are reshaping the packaging landscape. These technologies enhance consumer engagement through interactive features and real-time tracking.

One significant trend is the integration of QR codes. These codes offer instant access to product information. They create a bridge between physical packaging and digital content. A study by Smithers Pira found that 75% of consumers prefer products with interactive packaging elements. There is a palpable shift towards enhancing the shopping experience. Yet, challenges remain in adoption rates among smaller brands, often constrained by budgets.

Another exciting development is the use of sensors in packaging. These sensors monitor freshness and inform consumers about product safety. According to a report by MarketsandMarkets, the smart sensor market is expected to grow to $3.5 billion by 2025. However, not all consumers trust these technologies yet. Some are skeptical about data privacy. This creates a gap that brands must address. Investing in consumer education can help bridge this divide.

Integrating AI and IoT in Packaging Equipment

The integration of AI and IoT in packaging equipment is transforming the industry. With 60% of companies expecting to implement these technologies within the next two years, the shift is noticeable. Intelligent systems enhance efficiency, providing real-time data on production. This boosts decision-making and reduces downtime.

IoT sensors monitor machinery health, predicting failures before they occur. In a recent study, businesses reported up to a 30% reduction in maintenance costs. However, embracing this technology isn’t without challenges. Data security and interoperability issues often raise concerns. Companies must address these before fully realizing the benefits.

Moreover, AI algorithms analyze consumer trends and optimize packaging designs. Some claim this could lead to a 15% increase in product appeal. Yet, hesitation exists. Smaller businesses may struggle to adopt such advanced solutions due to costs. Balancing innovation and accessibility is key to full industry engagement.

Top 10 Packaging Equipment Innovations You Need to Know About

| Innovation | Description | Key Features | Benefits |

|---|---|---|---|

| AI-Powered Predictive Maintenance | Utilizes AI algorithms to predict equipment failures before they occur. | Real-time monitoring, Machine learning analysis | Reduced downtime, Cost savings |

| IoT-Enabled Smart Packaging | Integrates sensors into packaging to monitor product conditions. | Temperature control, Humidity sensors | Improved product quality, Enhanced customer experience |

| Autonomous Robotics in Packaging | Robots that autonomously pack products with minimal human intervention. | Self-learning capabilities, Adaptable to different tasks | Increased efficiency, Labor cost reduction |

| Eco-Friendly Packaging Solutions | Innovative materials that reduce environmental impact. | Biodegradable materials, Recyclable designs | Sustainability, Enhanced brand image |

| Blockchain for Supply Chain Transparency | Tracks products through the supply chain to ensure authenticity. | Immutable records, Traceability | Increased trust, Reduced counterfeiting |

| Augmented Reality for Packaging Design | Uses AR technologies for interactive packaging prototypes. | 3D visualization, User engagement features | Creative design processes, Consumer interaction |

| Smart Labeling with NFC | Labels that utilize NFC technology for enhanced information access. | Contactless communication, Data analysis | Consumer data collection, Increased sales opportunities |

| Flexible Packaging Machines | Machines capable of handling multiple types of packaging formats. | Quick format changeovers, Versatility | Adaptability to market trends, Cost efficiency |

| Data Analytics for Optimization | Utilizes data analysis to enhance packaging operations. | Performance monitoring, Process mapping | Improved productivity, Informed decision making |

| Digital Printing Technology | Advanced printing techniques for high-quality, personalized packaging. | High-resolution printing, Short run capabilities | Customization, Enhanced branding opportunities |

Related Posts

-

The Ultimate Guide to Pouching Machines in 2025 for Packaging Solutions

-

Why You Need a Box Packing Machine for Your Business Efficiency

-

2025 Guide: How to Choose the Best Manual Pouch Filling Machine

-

2025 Top Trends in Chemical Packaging Machine Industry You Need to Know

-

What is a Pouching Machine? Understanding Its Uses and Benefits

-

Top Benefits of Using a Box Packing Machine in Your Packaging Process