Top Robotic Packing Machines of 2026 What to Expect?

As we move into 2026, the landscape of packing technology is evolving rapidly. Robotic packing machines are at the forefront of this change. These machines are designed to increase efficiency and reduce labor costs in packaging operations. Many companies are now using advanced sensors and AI algorithms to enhance performance.

Imagine a robotic packing machine flawlessly sorting products at an astonishing speed. However, the technology isn't perfect. There are still challenges to address, such as the need for consistent quality control. Sometimes, these machines struggle with unusual packaging shapes or fragile items.

The future of robotic packing machines holds great potential. With ongoing innovations, they will likely become more adaptable and user-friendly. Yet, as we embrace this technology, we must also reflect on its impact on the workforce and industry standards. Balancing efficiency and ethical considerations will be crucial moving forward.

Top Trends in Robotic Packing Machines for 2026

As we look ahead to 2026, robotic packing machines will undergo significant advancements. The demand for automation continues to rise. According to industry reports, the market is expected to grow at a compound annual growth rate of 14.5% from 2021 to 2026. This surge reflects the ongoing need to improve efficiency and reduce labor costs.

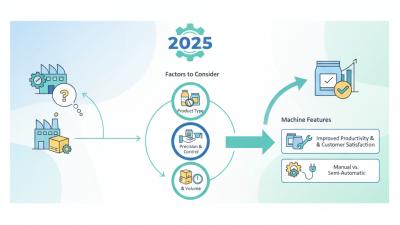

Flexibility is becoming a key trend in robotic packing solutions. Companies are integrating adjustable robots that can handle various package sizes and shapes. This versatility reduces the need for multiple machines, saving space and costs. However, transitioning to flexible robotic systems can present challenges. Workers must be trained to operate these advanced machines effectively.

Tip: Consider investing in training programs for staff to adapt to new technologies.

Sustainability will also shape the industry's future. Eco-friendly materials and energy-efficient machines are in high demand. Companies that prioritize sustainability may gain a competitive edge. Yet, the initial cost of sustainable technology can be a barrier. Businesses need to evaluate long-term benefits versus initial investments.

Tip: Analyze your operational needs to find cost-effective solutions.

These trends highlight the need for continual adaptation. Companies that embrace change will likely lead the market. However, maintaining flexibility poses risks. Balancing innovation with reliability is essential for success.

Key Features Driving Efficiency in 2026's Robotic Packing Solutions

As we approach 2026, robotic packing machines are evolving rapidly. Key features will enhance efficiency and productivity. Users can expect advanced AI-driven systems. These machines can analyze data in real time, making packing decisions faster. Flexibility will be crucial, allowing the equipment to handle various product shapes and sizes seamlessly.

Another important aspect is the integration of machine learning. This technology will adapt to changing packing requirements. Workers may find themselves collaborating more with these robots. It is essential to understand how human roles will shift. Training will be vital for maximizing this collaboration. Despite the advancements, challenges will arise. Robotics can fail or require maintenance, which may disrupt operations unexpectedly.

Sustainability also plays a significant role in future designs. Eco-friendly materials and energy-efficient systems will likely dominate. However, some manufacturers may struggle to keep up with these trends. Balancing cost and innovation could prove difficult. Reliability in these machines will be necessary for minimizing downtime. The road ahead for robotic packing machines will be promising yet complex.

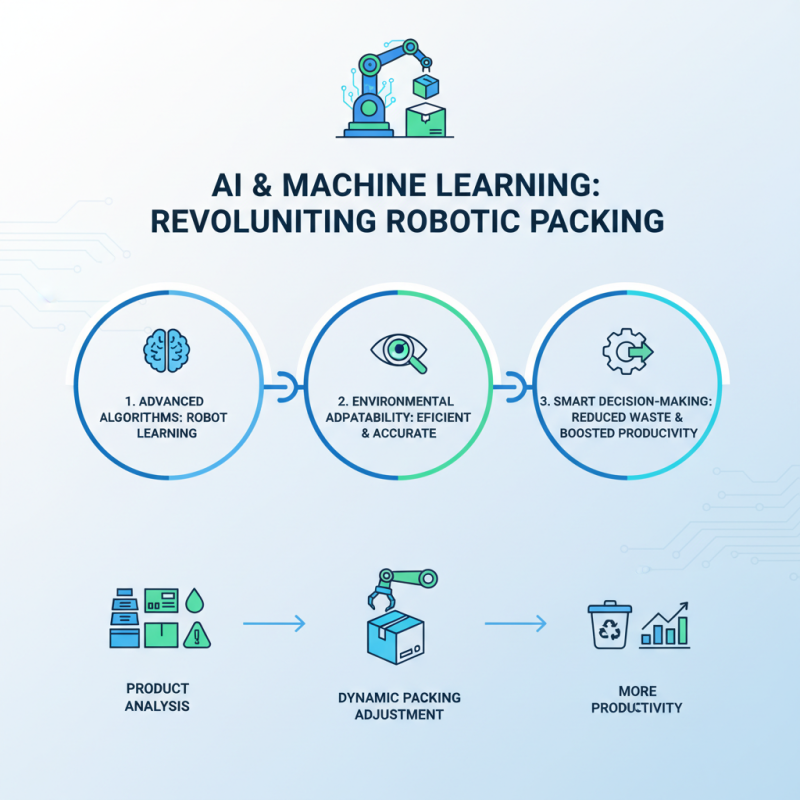

Impact of AI and Machine Learning on Robotic Packing Technology

AI and machine learning are transforming robotic packing technology in many exciting ways. Advanced algorithms enable robots to learn from their environment. This adaptability leads to improved efficiency and accuracy in packaging tasks. For instance, a robot can analyze the shape and weight of products and adjust its packing method accordingly. This smart decision-making reduces waste and enhances productivity.

However, challenges remain in integrating AI with robotic systems. Not all machines can respond to unexpected situations effectively. Sometimes, they struggle with complex packaging designs or variable product dimensions. These limitations highlight the need for continuous improvement in AI training. Moreover, the technology can be costly, and smaller businesses might find it difficult to keep up. Balancing innovation with practical implementation is crucial for future developments in robotic packing.

Industry Statistics on Robotic Automation Adoption by 2026

The pace of robotic automation in packaging is accelerating. By 2026, experts forecast a significant rise in adoption rates across various industries. A recent industry report indicates that over 40% of packaging operations will integrate robotic systems to improve efficiency. This shift reflects a growing demand for precision and speed in production lines.

Data suggests that manufacturers are increasingly investing in automation. In 2022, approximately 35% of industry players reported using robotic solutions. By 2026, this number is expected to rise to nearly 60%. The need to reduce labor costs and improve consistency drives these changes. However, challenges remain. Many companies struggle with the technical aspects of integration, alongside workforce training needs.

Despite the clear advantages, the path to automation isn't seamless. Transitioning to robotic systems can lead to initial downtime. The return on investment may take longer than anticipated. Adopting new technology demands careful planning. Businesses must overcome obstacles to fully realize the benefits of robotic packing machines.

Top Robotic Packing Machines of 2026

| Feature | 2024 | 2025 | 2026 |

|---|---|---|---|

| Adoption Rate (%) | 30% | 45% | 60% |

| Market Size (Billion USD) | 3.5 | 5.0 | 7.5 |

| Number of Units Sold (Thousands) | 50 | 80 | 120 |

| Average Price per Unit (USD) | 70,000 | 62,500 | 60,000 |

| Main Industries Using Robotics (%) | 30 | 40 | 50 |

Future Challenges in the Development of Robotic Packing Machines

The future of robotic packing machines presents significant challenges. Developers face the need for enhanced precision. Packing requirements are becoming more complex. Variability in product shapes and sizes complicates automation. Finding ways to handle fragile items remains crucial. Equipment may struggle with delicate packages, leading to damages.

Integration of AI is promising but still limited. Machines must learn from their environments. Current systems often require extensive programming. Simple errors can lead to costly mistakes. Testing and improvements take time. Moreover, adapting to real-time changes in production lines is difficult. Machines need to be versatile yet reliable.

Sustainability is another challenge. Many packing materials contribute to waste. Robotic systems should consider eco-friendly practices. There’s pressure to reduce carbon footprints. Incorporating recycled materials into packing processes can be complex. These evolving demands will require innovative solutions. Balancing efficiency and ecological responsibility remains a key concern.

Top Robotic Packing Machines of 2026

This chart displays the projected market growth and technological advancements in robotic packing machines from 2024 to 2026. Each category indicates the expected improvement in efficiency, cost reduction, and integration capabilities.

Related Posts

-

Why You Need a Box Packing Machine for Your Business Efficiency

-

2025 Guide: How to Choose the Best Manual Pouch Filling Machine

-

2025 Top Trends in Chemical Packaging Machine Industry You Need to Know

-

What is a Pouching Machine? Understanding Its Uses and Benefits

-

Top 10 Packaging Equipment Innovations You Need to Know About

-

Top Benefits of Using a Box Packing Machine in Your Packaging Process